Komori Gama Firing

- Date: 2023-06-11

- Tags: #pottery #blog

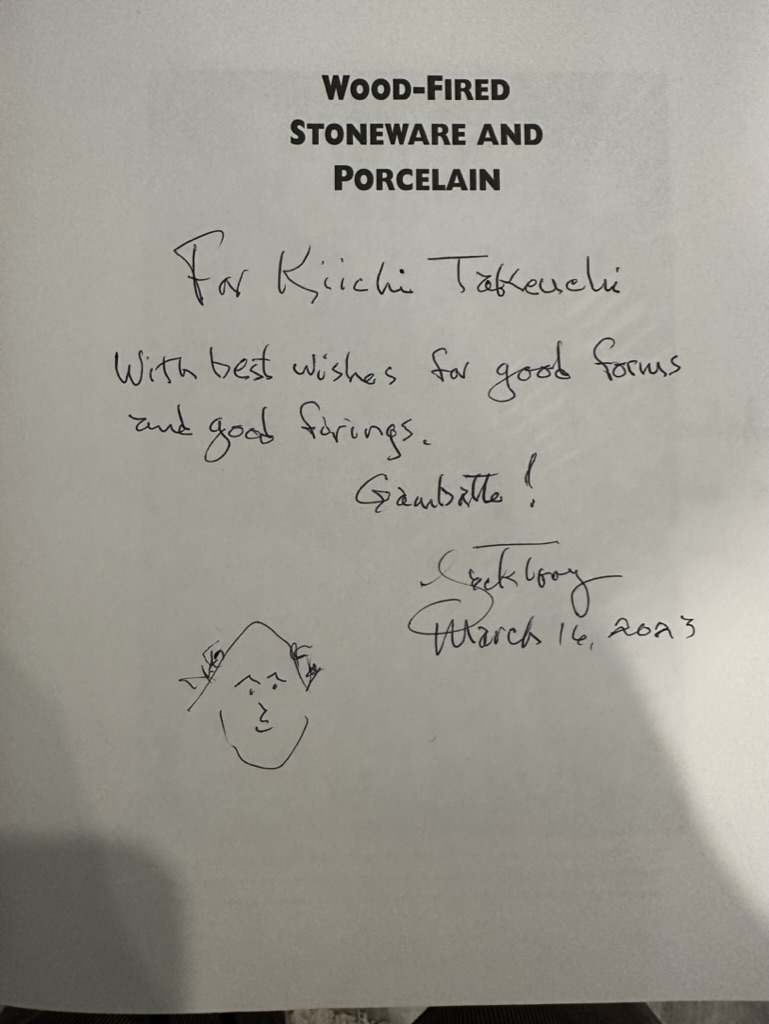

In early February 2023, I was preparing to present my 3-D printing ideas at NCECA 2023. While on shift one day, I had a conversation with Trevor Youngberg, who owns multiple Anagamas in Connecticut. He introduced me to a book titled Wood-Fired Stoneware and Porcelain by Jack Troy, written in 1995. Despite its premium price, I purchased the book, and it arrived just a day before I departed for the conference. To my surprise, NCECA featured Jack Troy's name prominently on the front page. Coincidentally, his panel discussion was scheduled right after my presentation in the adjacent ballroom.

Ganbatte!

Hoping to discuss the book with him, which I had skimmed through on my flight, I carried it with me during the conference. In the presenter's preparation room, I spotted a group reviewing slideshows. Among them, I recognized the tall gentleman as Jack. After introducing myself and expressing my enthusiasm for wood firing, Jack shared stories of his visit to Tokoname. To my delight, he autographed my copy of his book with a warm smiley face and the encouraging message "Ganbatte!"—Japanese for "Go for it!"

Upon my return to New York, Trevor received an email from Jack. It read, "I met a young Japanese potter at NCECA, but I didn't get his contact information." I had printed business cards before the conference, but either I completely forgot to distribute them or I chose not to give them out to every renowned potter I encountered, out of respect. In the email, Jack mentioned a potential opening for the next firing. Checking my calendar, I noted that the date coincided with the beginning of the New England Wood Firing Conference. It reminded me of something my university instructor once said: "Wood firing is a god-given opportunity for potters." This seemed to be an even greater opportunity, especially since it was taking place just before the conference and a mere 250 miles away. Was this a sign? Without hesitation, my answer was "Yes." I'm ready to embrace every opportunity, believing each to be a blessing from the kiln god.

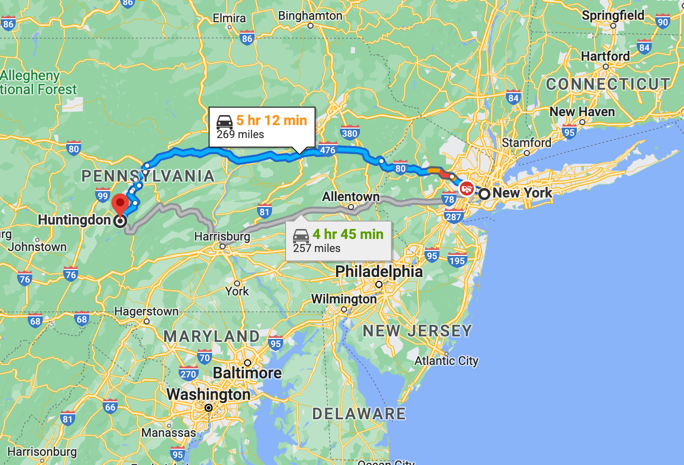

Adventure

Logistics presented the most significant challenge. I felt it was too risky to transport my bisqueware via Amtrak. However, his kiln, the Komori Gama, is spacious. Each potter is allotted a space of 3ft x 3ft x 3ft. It's huge! I managed to fill only half of that volume. I'd never driven 250 miles in my electric vehicle before, so I mapped out all the charging stations along Route 80 from New York to Pennsylvania. With every firing, I gain new insights or elevate my skills. I've grown accustomed to long drives, packing pots securely, and preparing my gear. This time, Jack included a poem alongside his firing instructions. I soon discovered that he'd studied English Literature in college, prompting me to buy another book: Given Sugar, Given Salt: Poems by Jane Hirshfield. By the way, this was my first poetry book purchase in my life. Why not broaden my horizons with poetry? At the very least, this book will enrich my English vocabulary.

Missing Kettle, Ring on Swing, and Snake Skin

As soon as I arrived at Jack's property, both he and his partner welcomed me. He then gave me a tour. I saw his small kiln, Pixie, and we proceeded to Komori Gama. This is the largest Anagama I've worked with so far. I observed the large stoke hole, side stoke holes, and the extended path to the chimney. There are three sections, and they gradually elevate towards the back of the kiln.

In his book, he talked about his kiln and added some great illustrations. While reading it, I found many poetic hints mixed in with all the useful info. For example, he named his kiln "Komori," which means "bat" in Japanese. When he built his kiln in 1978, he found a bat in the Anagama after its first firing. He spoke about his early excitement for Anagama in a workshop. His interest shifted to Anagama firing after he became less keen on salt glaze firing kilns, especially after releasing his first book, Salt-Glazed Ceramics in 1977. I'm not totally sure why he named the kiln after a bat. Even though bats sometimes have a spooky reputation, in Japan they're seen as good luck. I bet that was a special moment for him. Here's a revised version of your text:

In the book, he showed a nice kettle setup by the door. It was for the stoke crew to have some hot tea when it got cold. Unfortunately, he said it got removed ages ago.

I mentioned to him how cool I found all these ideas around the kiln. He then showed me this fun mini-game behind the stoke crew bench. It's a ring on a string, kinda like a swing. The challenge? You unhook the ring, swing it, and try to hook it back in 10 goes or less. He said some folks nail it first try, while others... not so much. I had a go and got it right on my 10th swing! That's gotta be a good omen for my first firing, right?

Another lucky sign? Jack showed me this entire snake skin hanging from a ceiling beam. It looked like the snake just decided to shed its skin right there and then. I shared with him that in Japan, people often keep snake skins in their wallets. They think it's a lucky charm for money.

Crawling into the Firebox

From Monday morning, I collaborated with others to load the kiln, lending a hand wherever needed. It took me half a day to familiarize myself with the process, but once I glazed and wadded all my ware, I began working on loading the front part. Due to my height, I opted to stay inside the firebox - a cozy and fun experience, reminiscent of the joy of crawling into small spaces as a child. I marveled at the ceiling's intriguing glaze spots, resembling crystals, while my knee pads, formerly used for rollerblading, proved quite useful throughout the entire process. When Jack brought in a long shelf, I managed to catch the other end. My LED light with a battery was also handy as the inside of the box at dusk.

Loading continued until Tuesday evening when Kevin Crowe, the leader of this firing, arrived. Interestingly, when I saw him for the first time, I felt as though I knew him. Though famous as a long-time wood-fire potter in Virginia, it was his smile that triggered a deja vu moment. I then realized he had appeared in a documentary video Out of the Fire

I had received the DVD when our University demolished my first campus studio. My ceramic art journey began at Long Island University's Brooklyn campus, but in 2021, due to a downsizing of the liberal arts program, I transferred to another campus. That led me to a retired instructor who introduced me to Trevor, a builder of Anagama in Connecticut. As I mentioned earlier, it all started with seeing Kevin in the DVD, followed by connections with Trevor and Jack, and ultimately leading to my meeting with Kevin in person. Meeting him felt like closing a loop in a series of events that unfolded over the past two years.

After we bricked up the side door, we followed a few ceremonial steps to start the fire. At Komori Gama, we use local materials to ignite the flame. For example, instead of using fire-starters or newspapers, we use leaves found on the ground around the kiln. Before lighting the fire, we gathered in a circle and performed some hand clapping ceremony to wish for a safe firing.

Then, Jack read a poem. The person chosen to start the fire is the crew member with the nearest birthday. Thanks to beginner's luck, it was me, as I was born in July.

I had the midnight pre-heating shift, and I savored some matcha green tea, a gift from my mom. Sitting alone on the couch in the rain, I felt really cozy. I'm expecting this beast to hit 2350°F in just a few days.

Fiesta

Every firing is different and stoking shifts bring dynamic energy to teams. I especially enjoy to see pots in potter's place during my visit. We had lunch together, work together, and then clean together. This is the first time Komori Gama had dumper at the chimney, and he said the temperature in front was too high. We switched to wet wood in the middle, but it didn't help to slow down. Kevin told crew to stop stoking from the side stoke holes on Thursday afternoon since the back side of the kiln reached our target temperature.

I explored the town of Huntingdon, eager to learn about the local lifestyle and historical trails. Though we originally planned to shut down the kiln on Sunday, we closed it a day early because we hit our goal. In the afternoon, Jack gave me a tour of the town, starting with the Amish market. Jack is a local celebrity; everyone knows him wherever he goes. We browsed through strawberries and other veggies, and then he took me to a "Secret Spot"—a cave about 20 minutes from town with a stream running through it. When I went down the cave, the air was humid but cool, blowing towards the stream. The ground was wet, and I reached a point where the sidewalk along the water ended. It was pitch-black. I turned off my cellphone light to listen to the water for a while. The cave seems to connect to another end, but nobody has successfully mapped the entire underground water path yet. We also made a pit stop at a bridge where I went down to the stream to pick some watercress. Just like my other mentors, pottery instructors often teach me a lot more than just pottery.

My Next Step

I'd like to extend a big "Thank You" or "Arigato" for including me in this firing crew and welcoming me to their hometown. While I'm proud to be part of the process, I don't want to be satisfied just because I'm wood-firing my works. When I started last year, I asked my instructor the same question, and he said, "That's a good thing; many people are just satisfied with firing their works in anagama." Now, I'm focused on improving my forms and basic skills. What's funny is that you're already planning the next firing, and I realized I have a bunch of new ideas for mine as well. It's like waiting for a Christmas gift every other month now.

Currently, I'm interested in developing my preferences:

Shino with Fine Wood Ash

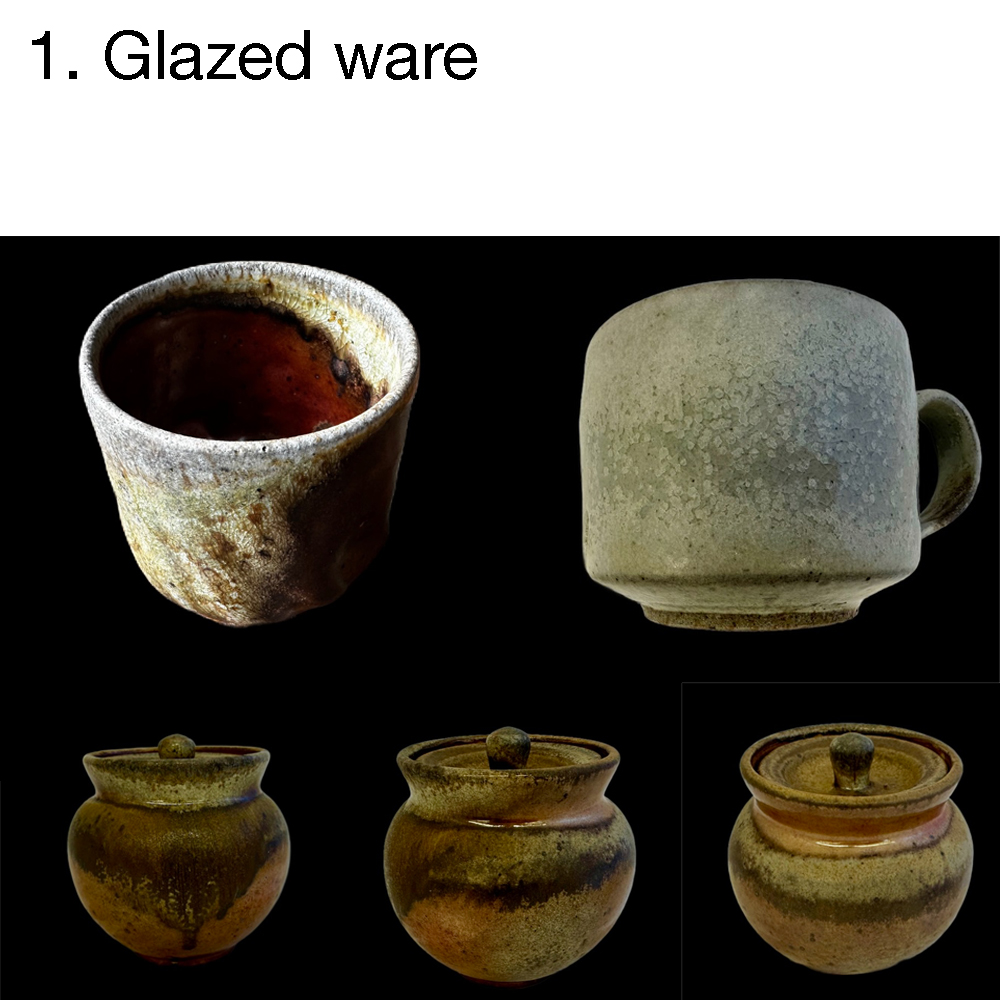

Jack talked about whether or not to glaze the exterior, but I had good results this time using Shino. I experimented with three variations: traditional white, Penn State Shino (salmon pink), and Shino with added iron. A whiskey cup captured a lot of ash and melted nicely. One mug developed interesting crystals with peachy flame marks around the foot—something I've never achieved at Trevor's Anagama. My jar also turned out well, with a smooth transition from the shoulder to the body. I plan to continue using Shino for around 20% of my pots while exploring slip decoration for another 50%. I may abandon other glazes like Yellow Salt. If I try something new, it will be Mino Shino.

Iron-rich Clay Body

Initially, I brought brown clay pots without glaze, made from Sheffield's 4D which contains redart, fire clay, and ball clay. Despite the company's recommendation for cone 6 oxidation, I was drawn to the earthy red, dark brown, and purple tones. Some fellow potters advised against using brown clay for wood firing, but I loved its texture, which I describe as Yaki-Imo, meaning baked Japanese yam skin. Rob's suggestion to place the brown clay works at the back of the kiln was eye-opening, and I plan to target specific locations based on temperature and ash accumulation in the future.

During lunch at Jack's house, I noticed a bowl similar to mine. Jack mentioned it was from one of his graduate students and showed me some of your early works, as well as a Bizen vase. Jack also suggested firing at a potentially lower temperature, like cone 9. I didn't make many brown pots this time, but I'm enthusiastic about creating more in the future. I'm excited to see the outcomes from the clay you gave me. I've begun throwing tumblers and tea bowls, aiming for a smoother surface. Attached is a photo from my previous firing alongside your work.

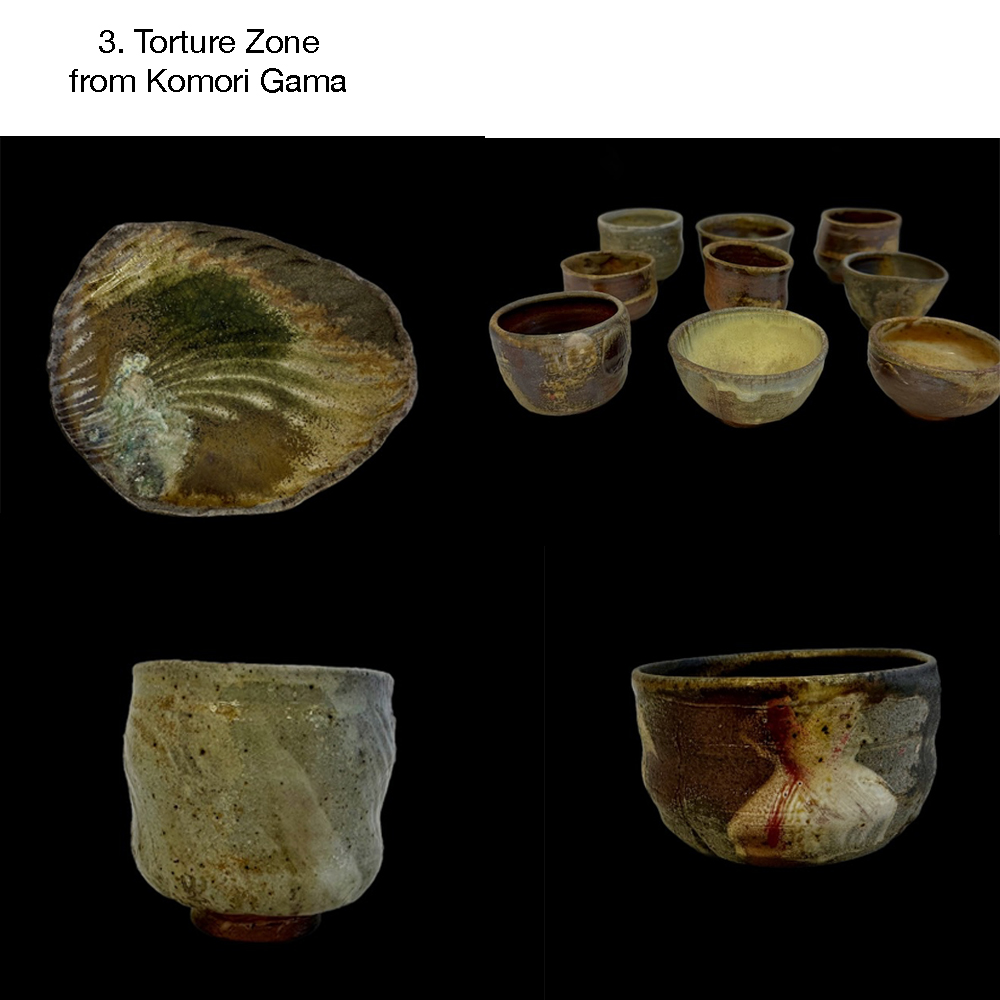

Torture Zone

The cup used for green tea during my last February firing turned out well. I appreciate its rough texture and try not to sand it too much, except for the rim. This time, I got various results ranging from a bowl with ash accumulation to well-fired gui-nomis and yunomis.

Modified Saggar or Kimono

This idea ties into the three points above and also connects to my initial discussion about why we're using Anagama kilns in 2023. I appreciate the unique effects and phenomena that occur during wood firing. However, I aim to exert more control over these effects, particularly in areas like the torture zone or even right in front of the firebox. My goal is to achieve a blend of extremely rough and smooth textures, clearly separated by contrasting patterns.

My thought process goes like this: Ancient Chinese and Korean potters mastered the art of creating beautiful celadon porcelain vases using saggars to protect them from wood ashes. Nowadays, we actively seek the effects of wood ash on our pottery. If we didn't, we'd opt for gas kilns—don't get me wrong, I enjoy gas firing but haven't explored it enough since universities often discard these kilns. So, in 2023, using completely closed saggars seems counterintuitive to me unless aiming for specific Hidasuki effects like those found in Bizen pottery. This led me to ponder whether I could create 'flame art' on my pottery by spraying the flame through a modified saggar, essentially using it as a stencil.

As far as I know, no one else is using a similar approach, but the idea excites me, and I find it fun to plan the next few variations. Since this is an early-stage concept for me, I've decided to call my saggars "Kimono," meaning clothes. Or maybe "Tuxedo," given that I learned pottery in this country!

As for using wadding, clam, and base crowns like Jack's plates, I'm eager to try them all. Numerous ideas are emerging for what comes next—like accounting for shrinkage rates, experimenting with rubbing copper glaze on the inside, or even creating mini pockets to place charcoal or salt nearby.

Things I'd Like to Explore

I haven't spent much time working with porcelain. However, after seeing many artists use it at Komori Gama, I decided to order B-Mix from Laguna to see what possibilities it offers.

Another avenue I'm exploring is wild clay, particularly different types from Long Island's north shore. I brought a few samples that were discreetly excavated by my instructor. This time, I placed them in containers, but next time I'll try firing them without containers since they didn't melt.

- White - This clay has some grog but resembles white stoneware or even porcelain in texture. It likely contains a high amount of feldspar. Unfortunately, I didn't have enough to create a single piece.

- Yellow - This variety has some iron content. I used it as slip, but it didn't have a significant impact on the surface.

- Pink, Brown - These likely contain a high iron content. I crafted a small vase that turned out completely black but wasn't brittle. I might tweak the composition to reduce the iron content, making this a continually evolving project.

- Dark Gray - This clay piqued my interest. Despite the noticeable iron spots on its white surface, the clay seems to contain organic impurities. When fired, the body turned white or light brown and interacted well with the natural wood ash and kiln atmosphere.